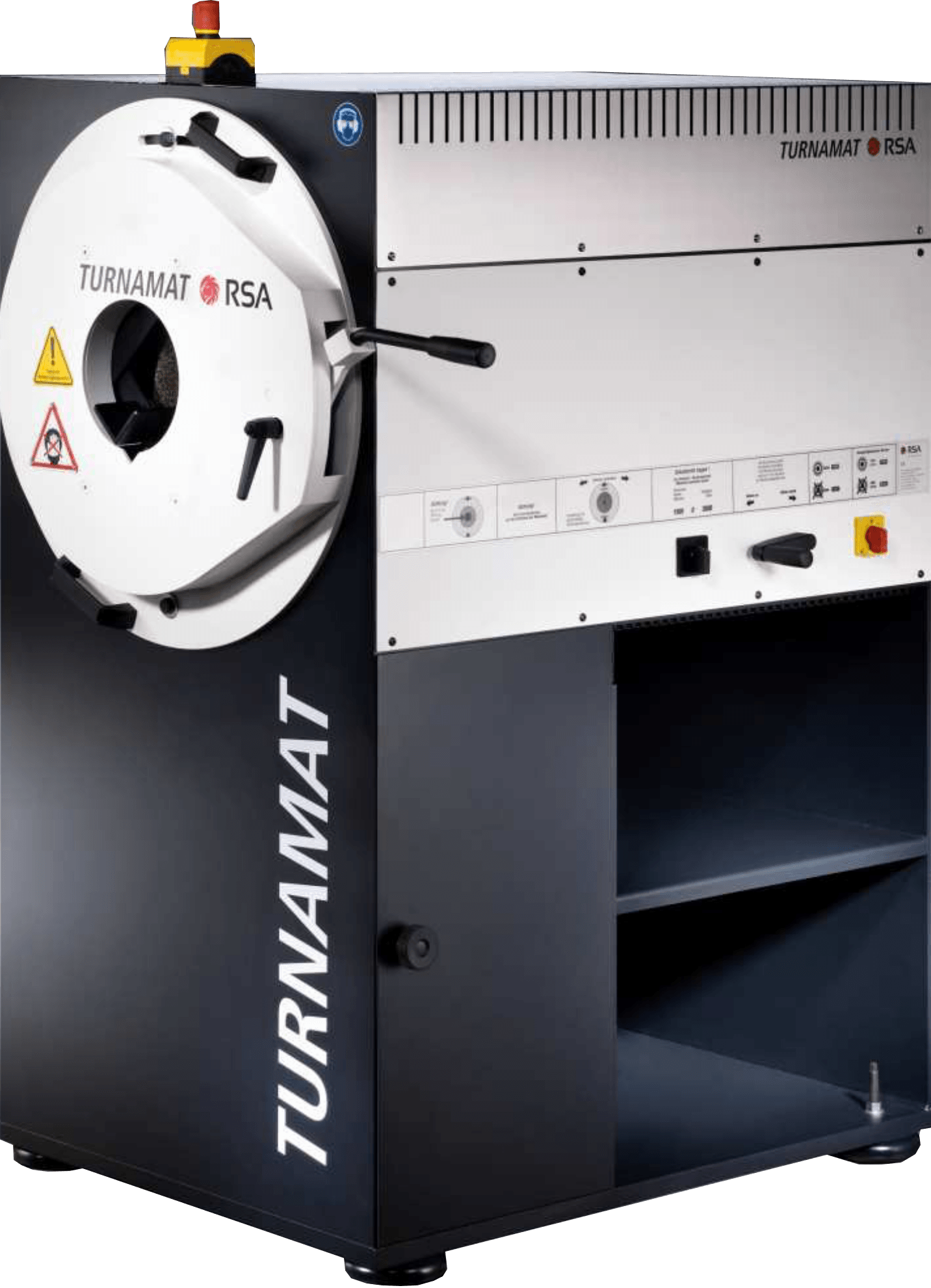

RSA TURNAMAT

Tube and section deburring machine for straight, bent and complex asymmetrical work pieces.

Deburring with high performance brushes

Faster. Easier. Better!

Deburring tubes, sections, bar ends and sheet metal after cutting is essential. But only the right system will provide low cost, reliable and immaculate deburring with both the machines and the high performance brushes being optimally designed adapted to the properties and quality of the work piece material.

RSA stands alone as the only company worldwide to manufacture both deburring machines and their high performance brushes. This benefits you as the user, as this complete system enables perfect results time after time.

Discover the advantages RSA deburring systems have to offer!

Overview

Robust and quick deburring for symmetrical and asymmetrical work pieces

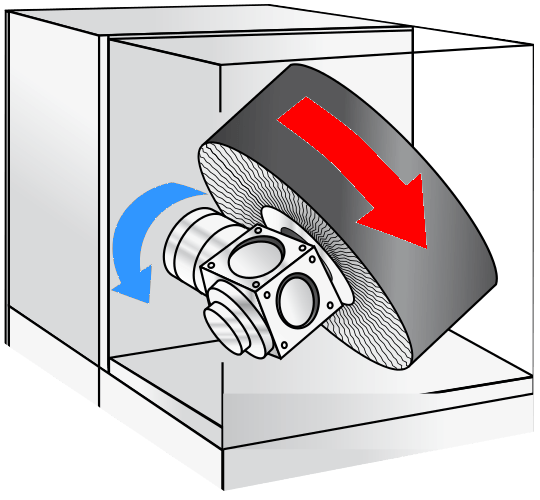

TURNAMAT is the tube deburring machine for an economic solution for deburring of straight and bent tubes, complex section shapes and work pieces which are heavy or have stronger burrs. Without manually turning the work piece both the inside and outside edges can be simultaneously deburred in around three seconds. With manual work piece feeding this means shorter set-up times! The Turnamat is also engineered to be a heavy, solid, long - lasting unit giving many years of trouble free service.

In addition to the typical rotation the radial brush also performs a second rotation: the entire drive unit also rotates to ensure the inner and outer edges of the work piece are machined evenly.

TURNAMAT symmetrical work pieces can be changed to a different work piece diameter via an adjustment control within seconds. The machine has a high safety standard with CE certification. Asymmetrical work pieces can be safely deburred on the TURNAMAT. sections are fed through a finely engineered front plate which can easily be changed without tools.

Specifications

Technical Data

Input power kW 3.7 / 4.4

Speed rpm 1,500 + 3,000

Work Piece Data

Materials steel, stainless steel, aluminum, non-ferrous metals

Cross-sections mm 20 x 20 to 120 x 120, 10 x 10 to 120 x 120

Deburring time sec 1 to 5 per end face

Other dimensions on request

Advantages

Your time advantage

Simultaneously deburrs inner and outer edges

No manually turning the work piece

Brush change in under two minutes

Your quality advantage

High performance brushes ensure consistent results

Residue-free deburring even on larger cross-sections

Your cost advantage

Built-in drawer for chips

No sensory linking required between deburring system and robot

Options

Changeable front plate

For precise alignment of asymmetrical work pieces

External dust extraction

Clamping and transverse feeding device

For work piece cross-sections to 70 x 450 mm

Lockable castors

For mobility

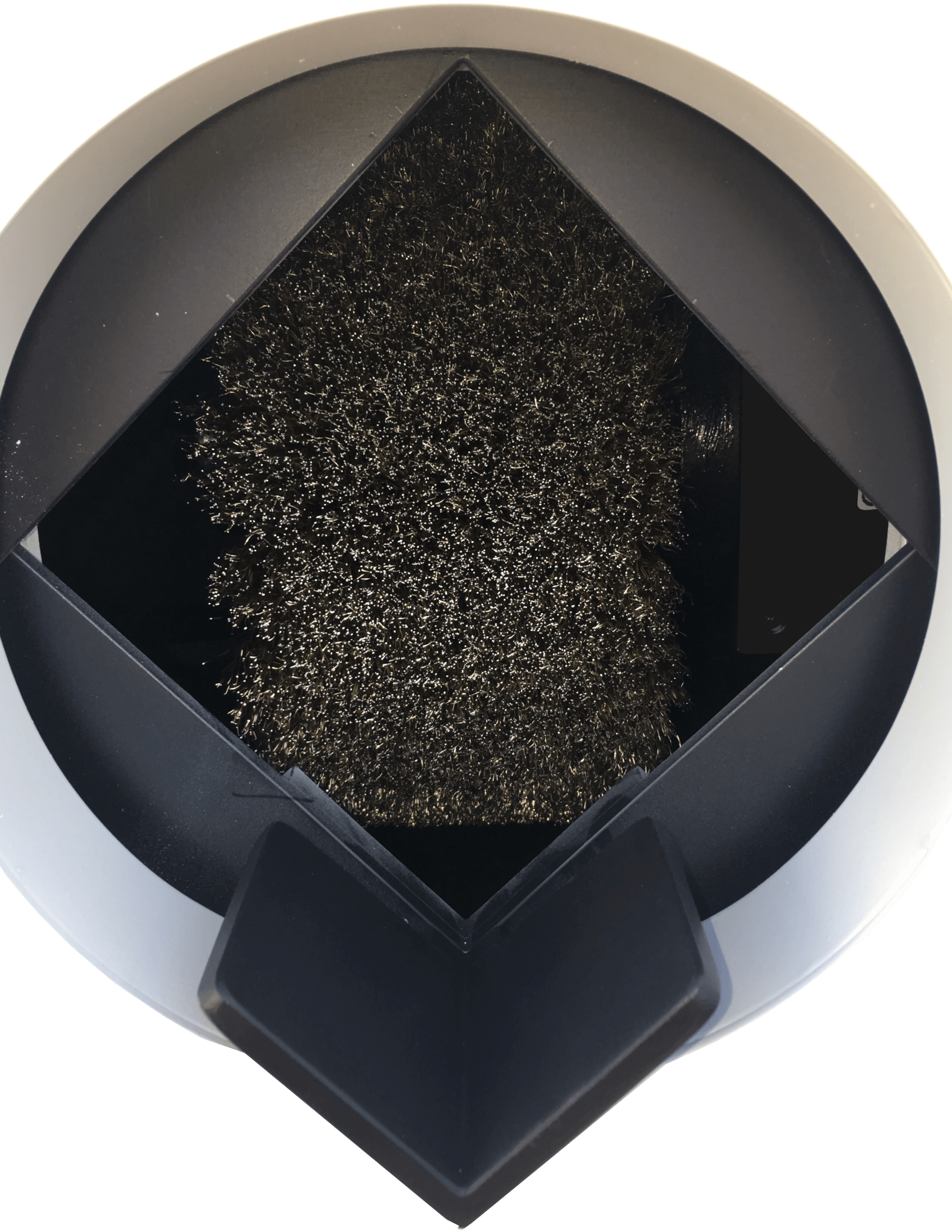

Brushes

High performance brushes from a system manufacturer

. . . . . .

Through intensive research and development RSA have further developed conventional technical brushes using special types of wire for various applications. This means excellent processing results, consistent quality and a longer working life . The result: low costs per processed work piece.

The benefits:

We control the complete manufacturing process and produce quality tools with the following features:

Quality wires with long working life

Very short processing times

True running throughout the lifetime of the brush

Trimming of the brushes according to specific requirements

Try it now!

Bring in your part for a free of charge trial production.